Polymer lithium-ion battery technology provided to you by electronic enthusiasts. Introduction to polymer lithium-ion battery technology. Energy and the environment are two serious issues that humans must face in the 21st century. The development of new energy and clean renewable energy is an important part of the world economy in the future. The technological fields with the most decisive influence

Polymer lithium-ion battery technology

Introduction Energy and environment are two serious issues that mankind must face in the 21st century. The development of new energy and clean renewable energy is one of the most decisive technical fields in the world economy in the future. Lithium-ion batteries have developed rapidly since their inception. This is because they just meet the requirements of the rapid development of mobile communications and notebook computers for miniaturization, lightweight, long working time, long life, no memory effect and no pollution to the environment. . The use of polymer solid electrolytes instead of liquid electrolytes to manufacture polymer lithium-ion batteries is a major advancement in lithium-ion batteries. Its main advantages are high reliability and processability, and it can be made into an all-plastic structure, making it possible to manufacture ultra-high-power lithium-ion batteries. The desire for a thin and flexible battery has been realized. 1. Structural characteristics of lithium-ion batteries. The positive and negative active materials of lithium-ion batteries are intercalated compounds. During charging, Li+ comes out of the positive electrode and is inserted into the negative electrode through the electrolyte. When discharging, the opposite is true. The charging and discharging process of the battery is actually Li+ in the two electrodes. The process of embedding and disengaging the electrodes back and forth, so this kind of battery is also called "Rocking Chair Batteries" (abbreviated as RCB). The reaction schematic diagram and basic reaction formula are as follows:

2. Polymer lithium-ion battery technology 2.1 Performance characteristics of polymer lithium-ion batteries Polymer lithium-ion batteries refer to lithium-ion batteries that use solid polymer electrolyte (SpE) as the electrolyte. The battery is composed of a positive electrode current collector, a positive electrode membrane, a polymer electrolyte membrane, a negative electrode membrane, and a negative electrode current collector. The battery is pressed and compositely formed, and is wrapped with an aluminum-plastic composite film and its edges are heat-melted and sealed to obtain a polymer lithium-ion battery. Since the electrolyte membrane is solid, there is no leakage problem, and the battery design has greater freedom. It can be connected in series and parallel or adopt a bipolar structure as needed. Polymer lithium-ion batteries have the following characteristics: ① Shaping flexibility; ② Higher mass specific energy (3 times that of MH-Ni batteries); ③ Wide electrochemical stability window, up to 5V; ④ Perfect safety and reliability; ⑤Longer cycle life and less capacity loss; ⑥High volume utilization; ⑦Wide application fields. Its working performance indicators are as follows: working voltage: 3.8V; specific energy: 130Wh/kg, 246Wh/L; cycle life: >300; self-discharge: <0.1%/month; working temperature: 253-328K; charging speed: 1h 80% capacity; 3h to reach 100% capacity; Environmental factors: non-toxic. 2.2 Cathode material The characteristics and price of lithium-ion batteries are closely related to its cathode material. Generally speaking, the cathode material should meet: ⑴ Have electrochemical compatibility with the electrolyte solution within the required charge and discharge potential range; ⑵ Mild electrode process kinetics; ⑶ High reversibility; ⑷ Good stability in air in full lithium state. With the development of lithium-ion batteries, research on high-performance, low-cost cathode materials is continuously carried out. At present, research mainly focuses on lithium transition metal oxides such as lithium cobalt oxide, lithium nickel oxide and lithium manganese oxide [1] (see Table 1). Table 1 Comparison of three main cathode materials for lithium-ion batteries

Lithium cobalt oxide (LiCoO2) belongs to the α-NaFeO2 type structure and has a two-dimensional layered structure, which is suitable for the deintercalation of lithium ions. Due to its relatively simple preparation process, stable performance, high specific capacity, and good cycle performance, most currently commercialized lithium-ion batteries use LiCoO2 as the cathode material. The synthesis methods mainly include high-temperature solid-phase synthesis and low-temperature solid-phase synthesis, as well as soft chemical methods such as oxalic acid precipitation, sol-gel method, hot and cold method, and organic mixing method. Lithium nickel oxide (LiNiO2) is a rock salt type structural compound with good high temperature stability. Due to its low self-discharge rate, low requirements for electrolyte, no environmental pollution, relatively abundant resources and affordable price, it is a promising cathode material to replace lithium cobalt oxide. At present, LiNiO2 is mainly synthesized through solid-phase reaction of Ni(NO3)2, Ni(OH)2, NiCO3, NiOOH and LiOH, LiNO3 and LiCO3. The synthesis of LiNiO2 is more difficult than LiCoO2. The main reason is that the stoichiometric LiNiO2 is easily decomposed into Li1-xNi1+xO2 under high temperature conditions. Excess nickel ions are in the lithium layer between the NiO2 planes, hindering the diffusion of lithium ions. It will affect the electrochemical activity of the material. At the same time, because Ni3+ is harder to obtain than Co3+, the synthesis must be carried out in an oxygen atmosphere [2]. Lithium manganese oxide is a modification of traditional cathode materials. Currently, spinel-type LixMn2O4 is widely used. It has a three-dimensional tunnel structure and is more suitable for the deintercalation of lithium ions. Lithium manganese oxide has abundant raw materials, low cost, no pollution, better overcharge resistance and thermal safety, and has relatively low requirements for battery safety protection devices. It is considered to be the most promising lithium-ion battery cathode material. Mn dissolution, Jahn-Teller effect and electrolyte decomposition are considered to be the main reasons for the capacity loss of lithium-ion batteries using lithium manganese oxide as the cathode material. 2.3 Solid polymer electrolyte Solid materials that conduct current with ions are usually called solid electrolytes. They include three types: crystal electrolytes, glass electrolytes and polymer electrolytes. Among them, solid polymer electrolytes (SpE) are light and easy to form films. , good viscoelasticity and other advantages, it can be used in batteries, sensors, electrochromic displays and capacitors. Using SpE in lithium-ion batteries can eliminate the problem of easy leakage of liquid electrolytes, replace the isolation membrane in the battery, inhibit the generation of dendrites on the electrode surface, reduce the reactivity between the electrolyte and the electrode, increase the specific energy of the battery, and make the battery more durable. It has the advantages of pressure resistance, impact resistance, low production cost and easy processing. Conventional solid polymer electrolyte (SpE) is composed of polymer and lithium salt. It is an electrolyte system formed by lithium salt dissolved in polymer. Generally, polymers containing polar groups such as oxygen, nitrogen, and sulfur in the molecular chain that can coordinate with Li+ can be used to form this type of system, such as: polyethylene oxide (pEO), polypropylene oxide, and polyoxyheterocycle Butane, polyethyleneimine, poly(N-propyl-1 aziridine), polysulfide hydrocarbon, etc. As a hard acid, Li+ tends to interact with hard bases, so the solubility of lithium salts in polymers containing nitrogen and sulfur polar groups is smaller than in polymers containing oxygen polar groups, and the conductivity (σ) It is very low and has no practical significance; the conformation of pEO molecules is more conducive to forming multiple coordination with cations than other polyether molecules, can dissolve more lithium salts, and shows good conductive properties, so the pEO + lithium salt system becomes SpE The earliest and most widely studied system. However, the σ room temperature of conventional solid polymer electrolyte (SpE) is usually less than 10-4S·cm-1. In order to meet the requirements of lithium-ion batteries, adding it to the polymer/salt system can promote the dissociation of lithium salt and increase the free volume of the system. By adding a plasticizer that reduces its glass transition temperature (Tg), a gel SpE with a room temperature of σ greater than 10-3S·cm-1 can be obtained. Plasticizers are typically organic solvents with high dielectric constant, low volatility, miscibility to the polymer/salt complex, and stability to the electrode. Such as ethylene carbonate (EC), propylene carbonate (pC), dimethyl carbonate, N-methylpyrrolidone, sulfolane, γ-butyrolactone, etc. Commonly used lithium salts include LipF6, LiN (SO2CF3), etc. Using testing methods such as XRD, DSC and AC impedance, a preliminary discussion was made on the factors affecting the conductivity of polymers. ⑴The effect of lithium salt concentration on conductivity When the concentration of lithium salt is low, the conductivity of the polymer electrolyte is relatively low, only on the order of 10-8. As the lithium salt concentration gradually increases, the conductivity also increases due to the increase in the concentration of current-carrying ions; and when the concentration of salt continues to increase, the high ion concentration leads to the interaction force between ions Enhancement reduces the mobility of current-carrying ions, resulting in a decrease in conductivity. ⑵The relationship between plasticizer concentration and Tg As the plasticizer increases, the glass transition temperature of the polymer electrolyte gradually decreases, accelerating the chain segment movement of the polymer electrolyte at room temperature, so its conductivity also increases with the increase. increase. Although the increase in plasticizer concentration greatly improves the conductivity of the polymer electrolyte, it also reduces the self-supporting film-forming property and mechanical strength of the polymer electrolyte membrane. If the prepolymer, plasticizer and lithium salt are blended, light or heat is used to initiate the polymerization reaction, and a gel SpE with a network structure is formed through chemical bonds, the resulting SpE not only has good mechanical properties, but also inhibits the polymer Crystallization increases the plasticizer content in SpE, and high σ SpE can be obtained. 2.4 Negative electrode material The capacity of a lithium-ion battery depends to a large extent on the amount of lithium embedded in the negative electrode. The negative electrode material should meet the following requirements: (1) The electrode potential changes little during the deintercalation process of lithium and is close to metallic lithium; (2) It has a relatively large High specific capacity; ⑶ high charge and discharge efficiency; ⑷ high diffusion rate of Li+ both inside and on the surface of the electrode material; ⑸ high structural, chemical and thermal stability; ⑹ low price and easy preparation. Current research work on anode materials for lithium-ion batteries mainly focuses on carbon materials and other metal oxides with special structures. The general method of preparing negative electrode materials is as follows: ① Heating soft carbon at a certain high temperature to obtain highly graphitized carbon; ② Decomposing cross-linked resin with a special structure at high temperature to obtain hard carbon; ③ Preparation of organic matter and polymers by thermal decomposition at high temperature Hydrogen-containing carbon. The difficulty that carbon anode materials have to overcome is the problem of capacity cyclic decay, which is an irreversible capacity loss due to the formation of a solid electrolyte interphase (SEI). Therefore, the preparation of high-purity and regular microstructure carbon anode materials is a direction of development. The mechanisms of various metal oxides are similar to those of cathode materials. The main research direction is to obtain metal oxides with new structures or composite structures. References [1] Venkatraman S, Subramanian V. Electrochemical Communications, 2000, 2: 18~22. [2] Xie Jingying et al. Power Technology, 1997, 21(5): 185~189.

Popular recommendation

Nickel cobalt lithium manganate (NMC) battery

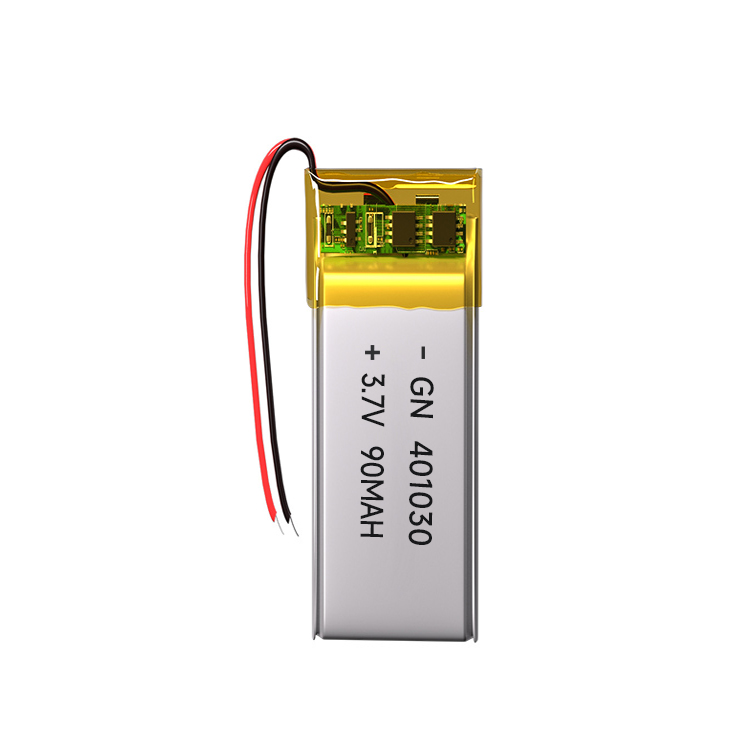

2022-11-21401030 lipo battery.A design based on a simple battery automatic constant current charging circuit

2023-10-08601848 polymer battery.Introduction to knowledge points of 18650 lithium battery production process

2023-10-08802540 lipo battery.Cylindrical lithium battery 21700 from a technical perspective

2023-10-09AG Coin foot battery

2022-06-18AG Coin TV environmental impact

2022-06-18Where does the battery come from the electrical

2022-06-181800mah 18650 battery.What is the difference between polymer lithium battery and 18650 lithium batte

2023-10-13AG Coin battery application

2022-06-18lithium 18650 li ion battery.Wang Qingsong, University of Science and Technology of my country: Rese

2023-10-08r03 battery!my country has made a breakthrough in solid-state lithium battery interface issues, prov

2023-10-08LR44 battery.ltc6802 Chinese information_Pin diagram_Internal structure diagram and application circ

2023-10-08